The direct print process eliminates label substrates, adhesives, and application time. This can add up to big cost savings . In addition there are no label edges to peel up and no UV wear issues so your product has a more complete and finished appearance as it ages. Check out the possibilities.

High quality direct print processes; Screen print, Silicone pad print, and Hot Stamp

Industry tested ink systems for maximum adhesion and product life

From simple to complex part holding fixtures to insure proper registration and print repeatability

Bulk packaging or custom unpack/repack to your specs. Multiple ship destinations no problem.

100% inline quality inspection with low reject percentages

Applications:

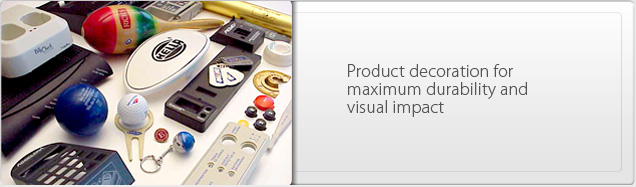

Injection molded Parts, Painted and unpainted metal panels and surfaces, Fabricated parts, Finished goods and products, Knobs/buttons/dials/templates, Advertising specialty products – Ipods, Cameras, MP3, Golf balls, Glassware and much more

“ Thanks for changing the labels for me on such a quick turn. I really appreciate that sort of 'above and beyond service' when you could have easily just said no. I’m looking forward to working with you in the future.”

Don D, Antec